Bronchitis Protection With Hatchery Spray Vaccination

Bronchitis Protection With Hatchery Spray Vaccination

Spray Vaccination is the most common to succeed in vaccine take

and prevention against respiratory infectious bronchitis (IB), a very prevalent poultry disease. However, the vaccination quality is highly variable worldwide, in every hatchery, and depends on several key factors that impact the good immunization and protection of the chicks.

by Mathilde Lecoupeur, Kevin Gandon, Kevin Liu, Ceva Animal Health,

Poultry Franchise

www.ceva.com

BRONCHITIS: UP TO 5-10% MORTALITY

Infectious bronchitis remains a huge concern, being one of the foremost causes of economic loss within the poultry industry.

The disease is caused by a coronavirus and severely impacts farmers’ margins in every area of the globe.

The mortality percentages in broilers can reach up to 10% during outbreaks. Without taking into account the side effects, only seen later, upon processing. Airsacculitis, an inflammation of the respiratory system of birds that can occur at any stage of the rearing process, is one perfect

example. Well-known as a result of a primary infection with infectious bronchitis, it leads to digestive disorders induced by kidney lesions and higher condemnation rates.

IB: X2 LOSSES AT FARM AND SLAUGHTER

Therefore, the economic results are twice impacted.

First, visually, at the farm level, decreasing the number of viable birds.Then, later and in a hidden way, which is often not well perceived and quantified, upon processing. The highest impact appears 1 or 2 days before catching, with dry and congested muscles.

Slowing down the processing line to remove the carcasses with airsacculitis significantly decreased the margin.

SPRAY VACCINATION: THE MOST COMMON ROUTE

To ensure a good protection of the birds, spray vaccination is, by far, the more common way of vaccinating against bronchitis.

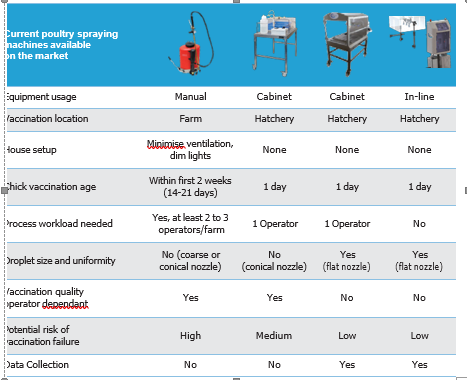

Done worldwide, either at the hatchery with cabinets or in-line machines (and conveyors)

or manually at the farm on day 1 or day 14, it allows fast and massive protection of the birds. However, the vaccination process itself depends on many factors and may partially or completely fail.

DROPLET SIZE AND RESPIRATORY TRACT

The main criterion is the droplet size: around 150µm. Too large and it won’t reach the target, the upper respiratory tract (Fig. 2); too small and it will go too deep, with potentially negative side-effects and the risk of droplet invasion of interstitial tissue.

To get an adequate droplet size, both the nozzles and the pressure of the machine should be adjusted before, during and after every vaccination. The machines should also be regularly and well maintained.

HATCHERY VACCINATION: THE BEST PROTECTION AGAINST IB

Besides early protection from a day-old, vaccinating in the hatchery, compared to on- farm vaccination, offers many advantages.

Increasing effectiveness, the new generation of sprayers offer a non-operator- dependent vaccination dispensing. Either with the in-line spray or gel, which can be placed on any existing conveyor for automated hatcheries without any stops.

during the process, or with the Smart Hatch Spray and Gel, a stand-alone cabinet where a motorised arm moves all along the crate,

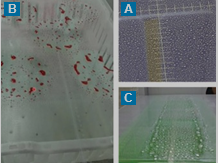

These two devices, equipped with flat nozzles, allow up to 100% of well-vaccinated chicks. Crate coverage, homogeneity and size of the droplets can be monitored with the Desvac Droplate in a very descriptive way (Fig. 3).

Data collection and alerts are also integrated into such hatchery equipment to ensure the right volume of delivery and alert the operator if any deviations from the process happen during vaccination.

These devices are equipped with an automatic cleaning-in-place system, which is a critical step in ensuring a high level of biosecurity in the vaccination circuit.

A. Efficient bronchitis spray vaccination at hatchery with flat

B. Poor coverage and droplet uniformity with conical nozzles

C. Poor droplet size

HATCHERY EQUIPMENT AND VACCINATION QUALITY

But the equipment itself is making a hugely significant difference in terms of vaccination quality.

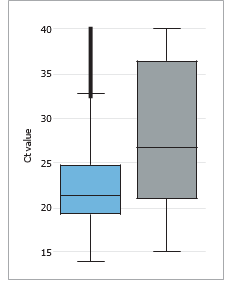

A recent real-world evidence study (RWE study) of 1,000 flocks for a total of 18,000 samples from 2020 to 2023 demonstrated the significant gap between two bronchitis hatchery spray vaccinations.

The boxplot (Fig. 5) summarizes the results for both groups, with Ceva Desvac sprayers (in blue) or without (in grey).

The Ct value being statistically lower (p<0.05) for the group spraying with the Desvac sprayer (see Fig. 4 for an interpretation of Ct values), means that the protection is higher with this equipment.

CONCLUSION

To ensure maximum protection, it is important to approach the vaccination process as a whole.

From best immunizing vaccine preparation to equipment service and maintenance, even the best vaccine, if not well applied, will not protect effectively.

*The picture of mammalian LRT was downloaded from smart Servier Medical Art

https://smart.servier.com without changes.

Servier Medical Art by Servier is licensed under

a Creative Commons Attribution 3.0 License

Scan the QR for more information

on the Smart Hatch Spray and Gel cabinet.

POULTRY

POULTRY